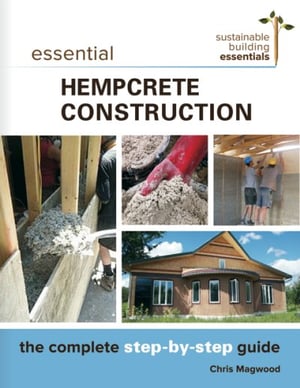

New book explains everything you need to know about "Hempcrete."

Hempcrete (or hemp-lime, as it’s commonly called in Europe) is a promising building insulation material. It is also the subject of more hype and hyperbole than any other sustainable building material. Proponents of hemp-based products tend toward unsupported or exaggerated claims of performance and planetary benefit with Websites that make the material seem miraculous.

In truth, hempcrete is simply a very good building insulation material, and there are plenty of compelling reasons to consider using it. It makes an excellent addition to the sustainable builder’s “tool kit” of more people- and planet- friendly building solutions. Hempcrete alone will not save the planet, but it will provide an excellent insulation material to a project with the right criteria and context. This book is intended to highlight both the advantages and disadvantages of hempcrete and provide potential users with reliable and tested information

What is Hempcrete?

Hempcrete is a unique building material, being a composite of a bio-fiber (hemp hurd or shiv) and a mineral binder (lime). These ingredients are blended together with water, and the moistened binder coats all the particles of hemp shiv. A chemical reaction occurs between the lime binder and the water, resulting in the binder setting and gluing the hurd particles together. Generically, it could be called “bonded cellulose insulation.”

When the binder is set and cured and any additional water has dried out of the mixture, the resulting material is hempcrete. Unlike many construction composites (such as concrete, mortar and plaster), the binder portion in hempcrete is not intended to fill all the voids between the hemp particles, but only to coat the particles and cause them to adhere to one another where they touch. A hempcrete mix typically has a high percentage of void space in the final mixture.

Hempcrete has a range of desirable thermal, structural and moisture-handling properties that make for an excellent building insulation material. Depending on the mix variables described in this book, hempcrete can be used as roof, wall and/or slab insulation.

Accounting for the Variables

Any discussion of hempcrete is complicated by the fact that all three elements in the bio-composite can have a range of types and characteristics, and can be added to the mix in varying ratios.

Hemp Hurd

The hemp hurd is the woody core of the hemp plant. It is typically sourced from hemp fiber producers after the valuable hemp fiber has been stripped from the outside of the hemp stalk, leaving the hurd as a by-product.

Lime binder

Lime has been an important binder in construction for thousands of years, largely in mortar and plaster recipes. There are different types and grades of lime, and there are various additives that may be included in the binder ratios. These variables will affect the setting time, strength and durability of the hempcrete mixture. There are several brands of manufactured lime binders made specifically for use in hempcrete, and there are recipes for creating lime binder from separate ingredients. The specific qualities that are ideal for a lime binder for hempcrete are discussed in the Material Specifications chapter of Hempcrete Construction.

Water

The volume of water added to a hempcrete mixture will have a dramatic effect on the results, even if the hurd and lime variables are controlled. Hemp hurd is extremely porous, capable of absorbing a volume of water that is much larger than what is required for a good hempcrete mixture. Too much water in a mixture can result in higher density, issues with setting for the lime binder, and excessively long drying times for the hempcrete.

Placement and Tamping

The final — and also critical — variable is the placement of hempcrete into the building. In wall and floor applications, the material requires some manual tamping in order to ensure that the mix is well bonded and has integrity. However, the amount of tamping can have a major impact on the density of the final material, even if all the mix ratios are identical. Variations in density can have a large impact on thermal performance, so this is an important variable to try to control. This will be covered in the Construction Procedure chapter of Hempcrete Construction, pictured here.

Limitations in Quantifying Hempcrete

A great deal of this book is intended to help builders find the ideal ingredients and mixtures in order to be able to use hempcrete successfully. But the variability in the formulations and ingredients make it difficult to make blanket generalizations about the performance parameters of hempcrete, especially compared to manufactured insulation products that come from a factory with little or no variation.

Chris is the author of several books on sustainable building

including More Straw Bale Building and Making Better Buildings and is the

series editor of The Sustainable Building Essentials Series.

Step-by-Step Manual Details Construction of Hempcrete Structures

New book explains everything you need to know about "Hempcrete."

Hempcrete (or hemp-lime, as it’s commonly called in Europe) is a promising building insulation material. It is also the subject of more hype and hyperbole than any other sustainable building material. Proponents of hemp-based products tend toward unsupported or exaggerated claims of performance and planetary benefit with Websites that make the material seem miraculous.In truth, hempcrete is simply a very good building insulation material, and there are plenty of compelling reasons to consider using it. It makes an excellent addition to the sustainable builder’s “tool kit” of more people- and planet- friendly building solutions. Hempcrete alone will not save the planet, but it will provide an excellent insulation material to a project with the right criteria and context. This book is intended to highlight both the advantages and disadvantages of hempcrete and provide potential users with reliable and tested information

What is Hempcrete?

Hempcrete is a unique building material, being a composite of a bio-fiber (hemp hurd or shiv) and a mineral binder (lime). These ingredients are blended together with water, and the moistened binder coats all the particles of hemp shiv. A chemical reaction occurs between the lime binder and the water, resulting in the binder setting and gluing the hurd particles together. Generically, it could be called “bonded cellulose insulation.”

When the binder is set and cured and any additional water has dried out of the mixture, the resulting material is hempcrete. Unlike many construction composites (such as concrete, mortar and plaster), the binder portion in hempcrete is not intended to fill all the voids between the hemp particles, but only to coat the particles and cause them to adhere to one another where they touch. A hempcrete mix typically has a high percentage of void space in the final mixture.

Hempcrete has a range of desirable thermal, structural and moisture-handling properties that make for an excellent building insulation material. Depending on the mix variables described in this book, hempcrete can be used as roof, wall and/or slab insulation.

Accounting for the Variables

Any discussion of hempcrete is complicated by the fact that all three elements in the bio-composite can have a range of types and characteristics, and can be added to the mix in varying ratios.

Hemp Hurd

The hemp hurd is the woody core of the hemp plant. It is typically sourced from hemp fiber producers after the valuable hemp fiber has been stripped from the outside of the hemp stalk, leaving the hurd as a by-product.

Lime binder

Lime has been an important binder in construction for thousands of years, largely in mortar and plaster recipes. There are different types and grades of lime, and there are various additives that may be included in the binder ratios. These variables will affect the setting time, strength and durability of the hempcrete mixture. There are several brands of manufactured lime binders made specifically for use in hempcrete, and there are recipes for creating lime binder from separate ingredients. The specific qualities that are ideal for a lime binder for hempcrete are discussed in the Material Specifications chapter of Hempcrete Construction.

Water

The volume of water added to a hempcrete mixture will have a dramatic effect on the results, even if the hurd and lime variables are controlled. Hemp hurd is extremely porous, capable of absorbing a volume of water that is much larger than what is required for a good hempcrete mixture. Too much water in a mixture can result in higher density, issues with setting for the lime binder, and excessively long drying times for the hempcrete.

drying times for the hempcrete.

Placement and Tamping

The final — and also critical — variable is the placement of hempcrete into the building. In wall and floor applications, the material requires some manual tamping in order to ensure that the mix is well bonded and has integrity. However, the amount of tamping can have a major impact on the density of the final material, even if all the mix ratios are identical. Variations in density can have a large impact on thermal performance, so this is an important variable to try to control. This will be covered in the Construction Procedure chapter of Hempcrete Construction, pictured here.

Limitations in Quantifying Hempcrete

A great deal of this book is intended to help builders find the ideal ingredients and mixtures in order to be able to use hempcrete successfully. But the variability in the formulations and ingredients make it difficult to make blanket generalizations about the performance parameters of hempcrete, especially compared to manufactured insulation products that come from a factory with little or no variation.

Order Hempcrete Construction from New Society Publishers HERE.

By Chris Magwood, Guest Columnist

Chris is the author of several books on sustainable building including More Straw Bale Building and Making Better Buildings and is the series editor of The Sustainable Building Essentials Series.